You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printers

- Thread starter Hurricane

- Start date

Hurricane

Well-Known Member

Just a quick update on the FreeCAD CAD design software.

About a year ago, FreeCAD "became of age" and released its Version 1.0. At that time, the FreeCAD project was some 20 years old but that was the first "official" release that gave it credibility and focus as a good alternative to expensive CAD design software packages.

Yesterday, the FreeCAD team announced that their next release (Version 1.1) has moved into the Release Candidate stage prior to a full release in the next few weeks.

See this link WIP Wednesday, 26 November 2025

There are a number of useful improvements in Version 1.1 that I have already found useful - this is one such improvement but there are many more.

A graphical way to Pad (extrude) a 2D Sketch

Test downloads for Version 1.1 are always available for download on the FreeCAD website - I've been downloading/testing them for my own use over the last year.but for most of my designs, I have been continuing to use the old Version 1.0.

In fact, I have grown to love FreeCAD - like any software, it takes a little while to get used to it but it does everything want. I often create quite complicated designs. I use it, more or less, on a daily basis.

So for those of us that don't want to spend large sums of money, FreeCAD is a great project for and 3D printing designs.

So if you haven't used it before, why not download a copy and play with it. FreeCAD is totally free to download and use and runs on Windows, Apple and Linux

About a year ago, FreeCAD "became of age" and released its Version 1.0. At that time, the FreeCAD project was some 20 years old but that was the first "official" release that gave it credibility and focus as a good alternative to expensive CAD design software packages.

Yesterday, the FreeCAD team announced that their next release (Version 1.1) has moved into the Release Candidate stage prior to a full release in the next few weeks.

See this link WIP Wednesday, 26 November 2025

There are a number of useful improvements in Version 1.1 that I have already found useful - this is one such improvement but there are many more.

A graphical way to Pad (extrude) a 2D Sketch

Test downloads for Version 1.1 are always available for download on the FreeCAD website - I've been downloading/testing them for my own use over the last year.but for most of my designs, I have been continuing to use the old Version 1.0.

In fact, I have grown to love FreeCAD - like any software, it takes a little while to get used to it but it does everything want. I often create quite complicated designs. I use it, more or less, on a daily basis.

So for those of us that don't want to spend large sums of money, FreeCAD is a great project for and 3D printing designs.

So if you haven't used it before, why not download a copy and play with it. FreeCAD is totally free to download and use and runs on Windows, Apple and Linux

Hurricane

Well-Known Member

Just FYI

This is a link to MangoJelly's explanation on the new FreeCAD 1.1 Release Candidate

And this is a link to his Youtube playlist of the new features

FreeCAD 1.1 New Version Features

This is a link to MangoJelly's explanation on the new FreeCAD 1.1 Release Candidate

And this is a link to his Youtube playlist of the new features

FreeCAD 1.1 New Version Features

Bigplumbs

Well-Known Member

I just got a Creality K2 combo with CFS right good it is

Hurricane

Well-Known Member

TK Blue MAX

Well-Known Member

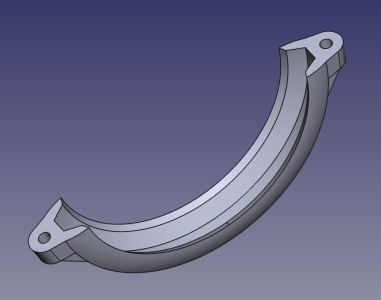

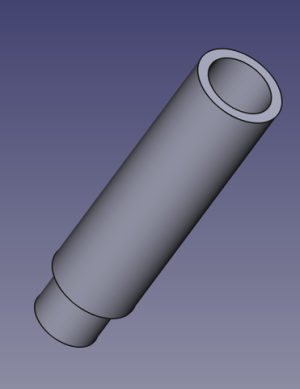

V band clamping ringI've just made one of these - can anyone guess what it is?

markc

Well-Known Member

Looks like a clamping ring for a Jabsco diaphragm pumpI've just made one of these - can anyone guess what it is?

This is a screen dump from FreeCAD

View attachment 203605

Printing was a little more complicated though (orientation and supports etc) but I have a result that is as strong as the original - made from ABS.

Dino

Well-Known Member

I’ve asked Santa for a Bambu Labs A1 printer. I need to order some filament. Was planning to go with the Bambu Labs filament but I was wondering what is a strong filament. I was thinking of printing a new bow roller wheel but I was worried that PLA might not be suitable

ylop

Well-Known Member

You are right to be worried about PLA for that application. Firstly it’s not particularly great outdoors for a long time. Secondly it’s not physically the strongest. It is the easiest stuff to print with though. Something essentially “structural” like that comes with some extra complications like which direction to print it in, how much infill to use (if you print a meaty bow roller at 100%, it will take forever), fancy options on your slicer might work but will be extra to master.I’ve asked Santa for a Bambu Labs A1 printer. I need to order some filament. Was planning to go with the Bambu Labs filament but I was wondering what is a strong filament. I was thinking of printing a new bow roller wheel but I was worried that PLA might not be suitable

If I wear printing it I’d use ABS and acetone vapour finish it, but when you consider what’s involved you might just pay someone to turn it. If you wanted to make a particular shape and test go fit etc then PLA would work, then give either the files or the PLA part to your local machine shop and you’d have it back before an ABS part is printed at 100% infill!

ASA seems to be the new trend to replace ABS and is more UV resistant so is probably the “right” answer.

Hurricane

Well-Known Member

I don't want to be the bearer of bad news but I think the Bambu Lab A1 is only capable of printing PLA.I’ve asked Santa for a Bambu Labs A1 printer. I need to order some filament. Was planning to go with the Bambu Labs filament but I was wondering what is a strong filament. I was thinking of printing a new bow roller wheel but I was worried that PLA might not be suitable

But I believe that it is a great printer.

I understand that you need an enclosed printer to print ABS or ASA.

I understand that the best value at the moment is the P2S but if cost is a factor, they are still selling the P1 at a good price.

They have a P1 Combo with the old AMS or an extra for the AMS 2 Pro

On my X1C, I have the old AMS which works fine - the big difference between the two AMS versions is that the AMS 2 is easier to maintain - that said, I've never had a problem with my old AMS. But any AMS is well worth the extra cost

PLA is quite strong but probably not strong enough for a bow roller.

You could, of course print several and replace them as they fail.

I'm not sure that ABS or ASA would be the correct material for a bow roller - probably a Nylon but thats expensive filament so I've never used it.

As said above, I have an X1C and I've been using ASA for external jobs that are exposed to the Med sun.

I also use ABS a lot - I really like ABS - it is the same price as PLA.

I still use PLA a lot as well and in certain cases, PLA can be quite strong.

PLA's printing temperature is a LOT lower than ASA and ABS so PLA models will print quicker.

I always use the Bambu filament because it comes with an RFID tag that the printer scans - thus setting the correct temperatures and flow rates etc.

Virtually faultless when using the Bambu Lab AMS unit.

I simply load the filament and print it using all the defaults - works 95% of the time.

So, to recap - I (almost always) use either PLA or ABS - because they are cheap and easy to print.

Hurricane

Well-Known Member

V band clamping ring

Nearly correctLooks like a clamping ring for a Jabsco diaphragm pump

It is the clamping ring for a Whale Gulper Pump.

My original ones broke so I bought a replacement and a spare sets.

I still have the spare set but I thought it would be in interesting challenge to see if I could make a replacement.

I'm actually quite pleased with the FreeCAD design - 2 profiles extruded round 2 paths and some mirroring.

I'm really loving working with FreeCAD - it takes some work to understand it, but very rewarding results.

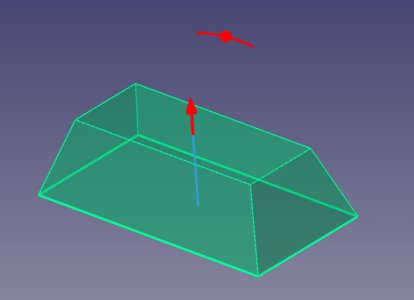

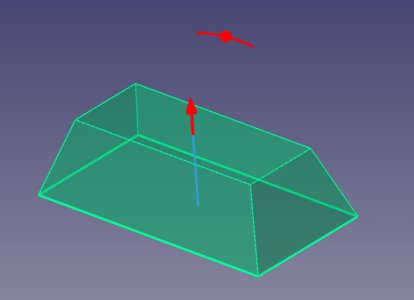

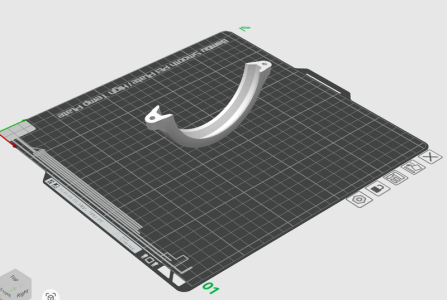

As said above, the print orientation and supports were a bit more complicated than usual

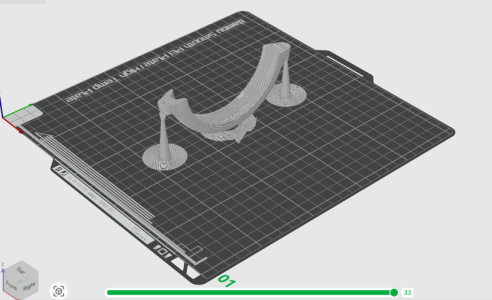

This is the orientation on the build plate that I chose

And these were the supports that I selected

This print orientation kept it strong and the inner surfaces as smooth as the original manufacturers one.

markc

Well-Known Member

Great work on FreeCad! I had a clamp ring break earlier in the year and I did consider trying to print one, but I felt that the layer lines introduce too much weakness., and didn't fancy the risk with the black tank pump!Nearly correct

It is the clamping ring for a Whale Gulper Pump.

My original ones broke so I bought a replacement and a spare sets.

I still have the spare set but I thought it would be in interesting challenge to see if I could make a replacement.

I'm actually quite pleased with the FreeCAD design - 2 profiles extruded round 2 paths and some mirroring.

I'm really loving working with FreeCAD - it takes some work to understand it, but very rewarding results.

As said above, the print orientation and supports were a bit more complicated than usual

This is the orientation on the build plate that I chose

View attachment 203627

And these were the supports that I selected

View attachment 203628

This print orientation kept it strong and the inner surfaces as smooth as the original manufacturers one.

Bigplumbs

Well-Known Member

Rather than get a Bamboo PI the P2S is out and also look at the U1 From Snap Maker. Now that is a Game Changer

Hurricane

Well-Known Member

I'm afraid that I'm a bit of a Bambu follower. I particularly like the "one stop" solution for printers and filaments - especially when used with the AMS automatic feeders. The Bambu filament prices are also well priced. Big discounts if you buy 4, 6, 10 or 14 - I try to buy refills which you load into the old spools. For PLA and ABS I usually get at least 6 bringing the price down to less than £11 each roll. At those prices, IMO, it isn't worth shopping around.Rather than get a Bamboo PI the P2S is out and also look at the U1 From Snap Maker. Now that is a Game Changer

And, yes, the P2S seems to be the best value Bambu printer at the moment.

Personally, if I were to buy a new one now, it would probably be the H2S - I'm not sure about the double headed machines like the H2D. I have no experience with them but I believe with two heads on the Bambu H2 printers, you have to consider carefully where you load the filament. The H2S though is a single head printer but with the bigger print volume and extra features like enclosure heating/temperature control. That said, I won't be changing my X1C for a long time yet - it does everything that I throw at it.

Last edited:

Hurricane

Well-Known Member

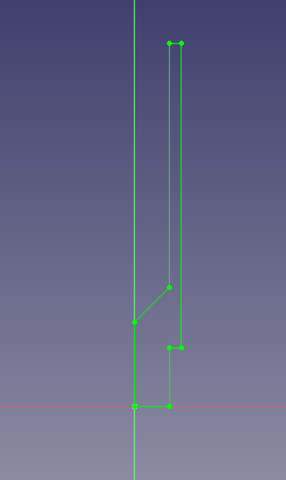

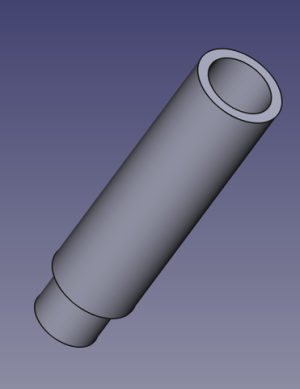

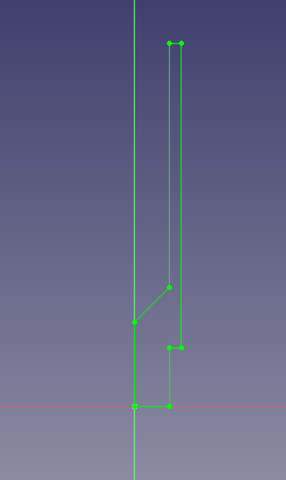

I find myself using the 3D printer for lots of things. For example, this week we unpacked our old synthetic 4 part Christmas Tree but this year, we decided to use just the top two parts. However, the second part didn't fit into the base - needed a short extension. So I opened FreeCAD and designed this in minutes:-

This is the 2D Sketch (dimensions and constraints not shown in this pic)

Then using the rotate tool - I got this:-

It took longer to measure the requirement than to design it.

I made it from ABS - and printed it vertically.

This is the 2D Sketch (dimensions and constraints not shown in this pic)

Then using the rotate tool - I got this:-

It took longer to measure the requirement than to design it.

I made it from ABS - and printed it vertically.

ylop

Well-Known Member

it’s not absolutely essential to have an enclosure for ABS (or I assume ASA). It will make it harder to get the right temp though, and can smell. You can to some extent improvise an enclosure. If you were intending to regularly print large parts in ABS an enclosed printer would definitely be preferable (and potentially less wasteful/frustrating).

The Op is planning for a £200 printer but you guys are suggesting £500-700 solutions!Rather than get a Bamboo PI the P2S is out and also look at the U1 From Snap Maker. Now that is a Game Changer

Hurricane

Well-Known Member

Agreed - it wasn't the OP - it was @Dino but, IMO, false economy comes into this.The Op is planning for a £200 printer but you guys are suggesting £500-700 solutions!

@Dino referred to the A1 - not mentioning if it was the A1 Mini or the A1.

The A1 printer (without AMS) is £209

A P1S (without AMS) is £339 - thats for an enclosed printer.

I would say that extra is well worth the extra, especially as you can then print the higher temperature filament.

Don't get me wrong - I have often thought of buying an A1 mini because it is extremely good value.

But I just think that this technology is so much of a game changer that a 120 quid extra is a "no brainer".

But, yes, I agree we have suggested more expensive machines.

petem

Well-Known Member

I need to make a small jig to hold a part in place.

Can anyone recommend a cheap 3d printing service?

Can anyone recommend a cheap 3d printing service?

FatherTed

Active Member

I use this company out of China. One of their other businesses makes PCB's for me.

Quality, delivery and price is very good in my opinion. If you do use them make sure you use the "Global Standard Direct Line" shipping option - it's the cheapest and takes 7-10 day, rather than DHL

Online 3D Printing Service | Custom 3D Printed Parts - JLC3DP

I had these remote control holders made recently. $15 and $17 (included shipping and VAT)

Quality, delivery and price is very good in my opinion. If you do use them make sure you use the "Global Standard Direct Line" shipping option - it's the cheapest and takes 7-10 day, rather than DHL

Online 3D Printing Service | Custom 3D Printed Parts - JLC3DP

I had these remote control holders made recently. $15 and $17 (included shipping and VAT)

Attachments

Last edited:

Bouba

Well-Known Member

That is exactly what I want to make…the flip up cover was broken by a cleaner years ago and I stare at it all day from my armchair. Unfortunately I don’t have any CAD experience and I don’t have a 3D printer…so I will just continue to stare at the broken oneYour CAD work looks very impressive. What software are you using? I've had my 3D printer for about 6 years now and have printed a few parts for the boat such as a new surround for the Rule bilge pump which has now been in place for 5 years. I like using ABS and I find I get good strength with about 50% infill for non load bearing parts. I've also done a lot with TPU to make some more flexible parts.