Hurricane

Well-Known Member

I'm really enjoying FreeCAD - just like all the other Open Source Software that I use.All of the above by @Hurricane but on a tighter budget I went for the Bambu P1S with AMS (P1S Combo)

There are a few differences from the more expensive models like larger screen (All driven from the computer I never look at my smaller screen) but functionally the same as far as my lack of experience can ascertain.

As a complete novice it really needed limited skill to get it working. FreeCAD was a bit harder to get the hang of the jargon but I made some simple clips within a couple of hours. (#130)

Best of luck

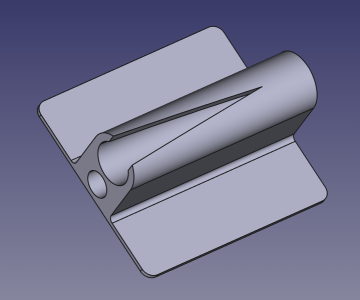

My FreeCAD designs are getting more and more complex.

Great value - its free so my only investment has been my time.

Just like switching to Linux 7 years ago, I don't regret it.

BTW I wonder how many people will be ditching their Windows 10 hardware later this year when it becomes un-supported by Microsoft.

Yes, it will work after that date but no security upgrades unless you pay for them (if they actually offer upgrades - that is).

The solution is to scrap Windoze and install Linux on those very computers and end up with something way quicker.

Loads of details out there on how and why you should do that.