dgadee

Well-Known Member

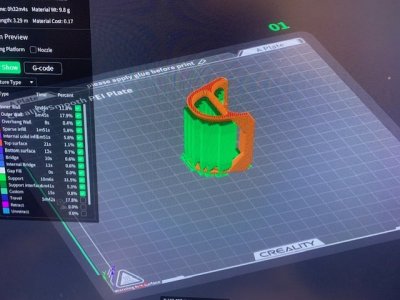

Well, after some 6 hours of playing about with FreeCAD, I have at last managed to see how it all fits together. Very complex options, but the most difficult part was working out how the 2d (sketch) and the 3d (parts design) elements fit together in the process. I am sure it will do all I need and more. Thanks for the pointer towards it.

On the Linux front, what I need is an option to update the music files on my mobile. MusicBee's Sync on windows was perfect, but I haven't been able to find anything as simple and straightforward for Linux. Any ideas?

ps: I know what you mean about dark themes. One tutorial I looked at used it - you could barely make out what he was clicking away at.

On the Linux front, what I need is an option to update the music files on my mobile. MusicBee's Sync on windows was perfect, but I haven't been able to find anything as simple and straightforward for Linux. Any ideas?

ps: I know what you mean about dark themes. One tutorial I looked at used it - you could barely make out what he was clicking away at.