Refueler

Well-Known Member

I have various supports also in STL form .... so I can choose whether to let the Slicer add supports - or add them to the print bed myself and move / size as to what I want ...

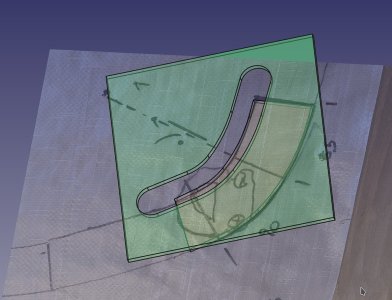

The Concorde I am printing - we are on Mk4 version ... a couple of parts are mirroed .. ie one is left and other is right .. so they stand on the bed facing each other ... if they were printed as is .. due to the height and items tending to move slightly - "banding" occurs .. where layers are just so slightly out as the item moves.

The trick there is to design a support wall between the two ... so they basically form a H on the bed and support each other. Once printed - you take your Xacto knife and cut the wall away .. sand and you have perfect smooth print with no banding.

You can do this also for a single item print .. create a T shaped item sitting on the bed.

The Concorde I am printing - we are on Mk4 version ... a couple of parts are mirroed .. ie one is left and other is right .. so they stand on the bed facing each other ... if they were printed as is .. due to the height and items tending to move slightly - "banding" occurs .. where layers are just so slightly out as the item moves.

The trick there is to design a support wall between the two ... so they basically form a H on the bed and support each other. Once printed - you take your Xacto knife and cut the wall away .. sand and you have perfect smooth print with no banding.

You can do this also for a single item print .. create a T shaped item sitting on the bed.