Refueler

Well-Known Member

You mention three bridges on your route. The odds of both the outer two having owners who'd be happy with you using them aren't great, but if you could it would make it a breeze to raise and drop.

First bridge is a girder lattice based railway bridge that is prohibited access. Second is a fixed span road bridge. Third is a lifting road bridge that only lifts for small ships access on Pilots request. Yachts are kept in Fishing harbour in the Port. I'm basically the only daft ***** who has a sailing yacht up river of the bridges.

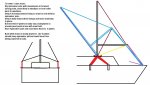

I could easily rig a derrick affair in my private mooring area - using the BBQ pontoon. But then the problem is to then raise the mast when away from there ...