Refueler

Well-Known Member

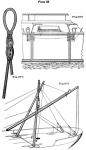

Compass some years ago advertised a mast lift system consisting of telescopic alloy poles and block / rope tackle. Idea being to lift mast vertically and then be able to lay flat.

I tried buying this some years ago - but they refused to ship to me in Latvia.

Has anyone used this system ?

Why do I ask ?

My yacht has a heavy mast and furling system forestay. Instead of my preferred tabernacle for mounting - it has the 'blade' system where mast foot has a slot and then a bolt to pivot. Its able to pivot and lay down mast - but extreme care has to be taken to not allow mast to fall t one side or other.

Because my yacht sits in private channel at rear of my house and also there are 3 bridges to get under - I have to raise / lower by hand. It takes at least 3 stout guys to do it.

I've tried posts fixed to pulpit - bent pulpit rails one year !

Of course best is crane or yard based derrick ... but not available ...

Anyone else with similar problem and how do you get round it ?

I tried buying this some years ago - but they refused to ship to me in Latvia.

Has anyone used this system ?

Why do I ask ?

My yacht has a heavy mast and furling system forestay. Instead of my preferred tabernacle for mounting - it has the 'blade' system where mast foot has a slot and then a bolt to pivot. Its able to pivot and lay down mast - but extreme care has to be taken to not allow mast to fall t one side or other.

Because my yacht sits in private channel at rear of my house and also there are 3 bridges to get under - I have to raise / lower by hand. It takes at least 3 stout guys to do it.

I've tried posts fixed to pulpit - bent pulpit rails one year !

Of course best is crane or yard based derrick ... but not available ...

Anyone else with similar problem and how do you get round it ?