Zing

Well-Known Member

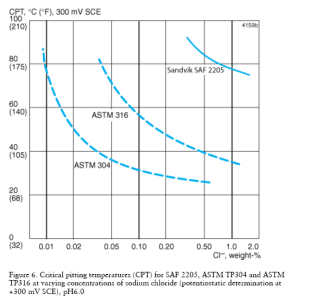

That's because performance is similar across the various corrosive test conditions, nonetheless here's another extract from another data sheet, this time for salt and going down to ambient temperatures. The relative performance is clear to see.Those are all highly specialised conditions. I thought we were discussing marine fittings at ambient temperatures. See this paper for example but there are many others:

Stainless Steel Material In Sea Water

304L, LDX 2101® and 316L can all tolerate somewhat more corrosive conditions in systems which do not contain obvious crevices, provided all welds are of good quality and well cleaned.

•........

• 2205 or lower alloyed grades are usually not sufficiently corrosion resistant.

Pitting resistance equivalence numbers are also far better (35 vs 24 for 316 and about 17 for 304). See here: What is A Pitting Resistance Equivalent Number (PREN)? - Unified Alloys