Refueler

Well-Known Member

I know they recc'd Marine Quality Waterproof grease ...

My seal has been run for decades on medium - high visco trailer grease and no groove or detrimental effects at all ... I can imagine Engineers now howling with pain !!

Today I went for a pot of the good stuff as my old one's run out and I need to reduce the fast drip into the bilges to near zero while she sits through winter.

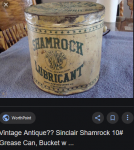

What happened to the days when you could buy a pot of grease and it had the plate on top of the grease so you could fill your Gun / grease tube without it getting covered ?? Now I get shown large toothpaste tube type ... plastic pots ... long thin tubes for gun use .. but no pot with a tin plate in ...

Of course Marine Grease was shown ... piddly little tube at silly price - yes we have this situation here in Latvia as well ... put Marine on the label and up goes the price ... which I politely said no ... and asked what med trailer grease did they have ... out comes a pot of Soviet Grease ... 5x the amount and 1/4 the price ... AND its waterproof grade !! But no tin plate for filling tube ..

There are two things I hate getting on hands ... Diesel and Grease.

My seal has been run for decades on medium - high visco trailer grease and no groove or detrimental effects at all ... I can imagine Engineers now howling with pain !!

Today I went for a pot of the good stuff as my old one's run out and I need to reduce the fast drip into the bilges to near zero while she sits through winter.

What happened to the days when you could buy a pot of grease and it had the plate on top of the grease so you could fill your Gun / grease tube without it getting covered ?? Now I get shown large toothpaste tube type ... plastic pots ... long thin tubes for gun use .. but no pot with a tin plate in ...

Of course Marine Grease was shown ... piddly little tube at silly price - yes we have this situation here in Latvia as well ... put Marine on the label and up goes the price ... which I politely said no ... and asked what med trailer grease did they have ... out comes a pot of Soviet Grease ... 5x the amount and 1/4 the price ... AND its waterproof grade !! But no tin plate for filling tube ..

There are two things I hate getting on hands ... Diesel and Grease.