Allan

Well-Known Member

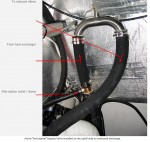

I've just been reading another thread about fitting a Volvo shaft seal. There's a recommendation for:

https://www.sillette.co.uk/price_pdf_files/deep_sea_mane_craft_shaft_seal.pdf

I'm interested in fitting something like that to our Starlight 35. Can anyone enlighten me as to where the water supply should come from? It's a Volvo 2030C with indirect cooling. I assume the water should come from after the pump but before the heat exchanger. I'm stuck as to how this can be achieved.

Allan

https://www.sillette.co.uk/price_pdf_files/deep_sea_mane_craft_shaft_seal.pdf

I'm interested in fitting something like that to our Starlight 35. Can anyone enlighten me as to where the water supply should come from? It's a Volvo 2030C with indirect cooling. I assume the water should come from after the pump but before the heat exchanger. I'm stuck as to how this can be achieved.

Allan