steve yates

Well-known member

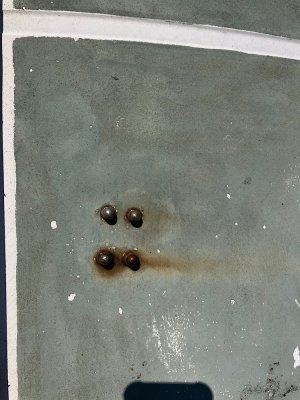

Screwed a batten up to the roof couple of weeks ago, noticed some dark gunge on cushion below it yesterday. Today there was a steady drip of liquid from end of batten. Took screw out and sure enough, liquid dripping out of the screw hole. This is from where the deck curves down just above the window.

I am assuming water in the balsa core, probably from elsewhere , and finding an outlet via the screwhole.

Two questions,

1) How to desl with it? Im thinking cut off the end of the batten that got damp, and drill a bigger hole right through to the deck to try and see the state of the balsa, but then what?

2) Its scorching, had no rain for 3 weeks, why has it suddenly appeared in the last couple of days?

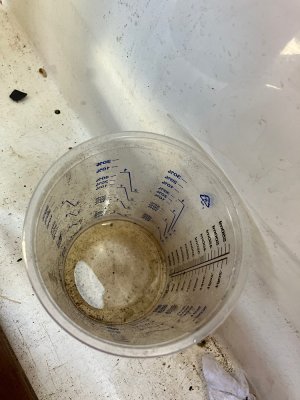

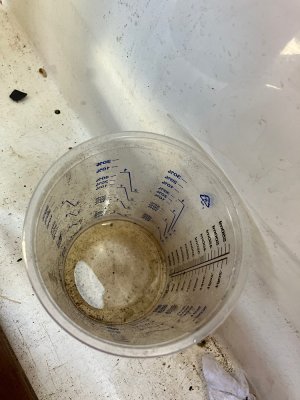

the pics show the batten, the drip and the amount dripoed in 10 mins this morning.

I am assuming water in the balsa core, probably from elsewhere , and finding an outlet via the screwhole.

Two questions,

1) How to desl with it? Im thinking cut off the end of the batten that got damp, and drill a bigger hole right through to the deck to try and see the state of the balsa, but then what?

2) Its scorching, had no rain for 3 weeks, why has it suddenly appeared in the last couple of days?

the pics show the batten, the drip and the amount dripoed in 10 mins this morning.