Jon.M

New member

Hi all,

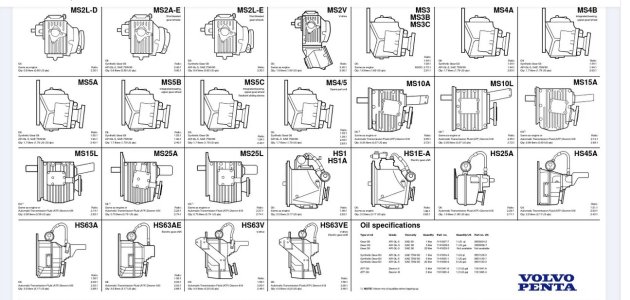

I have a 98 Broom 38 with TAMD41P and the HS1a transmission. I got the boat in Dec 22 and the surveyor noted that there was a noise/vibration at "high speed" which in this case was 17-18knts. As there was no vibration at lower speeds and the boat is now idling up and down the River Thames this has not been a big concern. Prior to my purchase, the boat had not been used much due to covid; the last change of oil in the gearbox & engine was unclear so I serviced and had various more pressing issues fixed in Jan 23. Now after a full season and a half, I have sent oil samples for engines and gearboxes away for testing. The good news is that the engines both got a clean bill of health however the gearboxes both show signs of wear with Copper, Iron, Lead present in the samples.

From what I can tell there are some parts available for the HS1a, mainly gaskets, pump and the friction/steel disk clutch pack.

So I'm seeking the collective wisdom here, do I:

a) Ignore it for the moment as on the Thames the wear rate is much lower and only worry about it when I plan to take the boat to sea (probably not likely till 26)

b) get a marine engineer to pull the gearboxes and strip/investigate/rebuild (the ones I have spoken to so far don't seem keen on this)

c) remove the gearboxes and send them to an automotive/engineering specialist to strip/investigate/rebuild on the basis that they probably do transmissions much more often than a marine engineer

d) replace the HS1a gearboxes with an alternative transmission e.g. ZF45a which probably adjusting engine height mounting

All ideas welcome at this point!

JM

I have a 98 Broom 38 with TAMD41P and the HS1a transmission. I got the boat in Dec 22 and the surveyor noted that there was a noise/vibration at "high speed" which in this case was 17-18knts. As there was no vibration at lower speeds and the boat is now idling up and down the River Thames this has not been a big concern. Prior to my purchase, the boat had not been used much due to covid; the last change of oil in the gearbox & engine was unclear so I serviced and had various more pressing issues fixed in Jan 23. Now after a full season and a half, I have sent oil samples for engines and gearboxes away for testing. The good news is that the engines both got a clean bill of health however the gearboxes both show signs of wear with Copper, Iron, Lead present in the samples.

From what I can tell there are some parts available for the HS1a, mainly gaskets, pump and the friction/steel disk clutch pack.

So I'm seeking the collective wisdom here, do I:

a) Ignore it for the moment as on the Thames the wear rate is much lower and only worry about it when I plan to take the boat to sea (probably not likely till 26)

b) get a marine engineer to pull the gearboxes and strip/investigate/rebuild (the ones I have spoken to so far don't seem keen on this)

c) remove the gearboxes and send them to an automotive/engineering specialist to strip/investigate/rebuild on the basis that they probably do transmissions much more often than a marine engineer

d) replace the HS1a gearboxes with an alternative transmission e.g. ZF45a which probably adjusting engine height mounting

All ideas welcome at this point!

JM