lustyd

Well-Known Member

Yes, obviously. But that will fill up because the only exits for the water are much higher.

Yes, obviously. But that will fill up because the only exits for the water are much higher.

I have an old Vetus M4.14. recently replaced the exhaust elbow that was cast iron and had rotted, new one is bronze. there was a composite gasket between the cast iron elbow and the alloy heat exchanger exhaust part. no corrosion there at all, in fact it looked brand new after 30 years ! I think the gasket is the solution.Here it is: Wide collection Boat Exhaust systems at VETUS boat parts

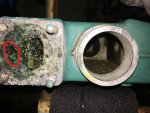

The flange that corrodes away is this one here circled in green, and my Bavs set up is identical to the below:

So, hot engine, turned off, hot water vapour travels back up the exhaust, into the Heat Exchanger and condenses?

Two dissimilar metals, and now we have an electrolyte to complete the destructive equation?

Leading to:

Do we agree this is what's happening to cause this corrosion? If this is the case, what can be done to prevent it? I feel an email to Vetus coming on...

I have an old Vetus M4.14. recently replaced the exhaust elbow that was cast iron and had rotted, new one is bronze. there was a composite gasket between the cast iron elbow and the alloy heat exchanger exhaust part. no corrosion there at all, in fact it looked brand new after 30 years ! I think the gasket is the solution.

That’s what the technical guys at Parts4Engines said. I purchased a new stainless exhaust elbow from them that they resell. It was packaged with a steel gasket by the manufacturer, however, Parts4Engines supplied their OWN composite gasket alongside, recommending I bin the metal gasket and use their composite one for the reason of protection from galvanic corrosion.

So that is the solution, however, do we agree that water has got up to that point through evaporation from the waterlock? Short of the chambers being compromised, that’s the only place it could come from isn’t it? As Vic states, there must be an electrolyte.

Condensation from any water based solution will consist purely of H2O (distilled water).Ive answered many questions about seawater getting back to the engine (or generator) The area affected is on the bottom of the flange where it could collect. Think about this, warm seawater sitting in the water trap, not to far away from that area. Engine shut down, a nice warm salty moist environment waiting to condense there. So why does it affect some and not others? Perhaps a look at the total exhaust system. Is it possible for sea water to splash back/ condense? Vetus do a good diagram in their catalogue showing best practice. Perhaps also the elbow should be part of a planned preventative maintenance program?

Splash back? Also salt water atmosphere is corrosive. Hence cars by the coast, ordinary steel on our boats, they all corrode more easily, I am sure that there are cleverer folk than us that can explain it.Condensation from any water based solution will consist purely of H2O (distilled water).

As for Gary’s comment that no one else has shared my heat exchanger pain on the forum, the reason I looked in the first place was partly due to horror stories on the Bavaria forums where others had the same challenge, such as the below:

Knock-on effects of heat exchanger/manifold corrosion

The link you quoted was about heat exchanger/manifold corrosion. Isn't this a different problem?

This sounds as though it explains what is going onQuite right, apologies, it was this one that alerted me:

Volvo Penta D2 55 Corrosion at Sea-Water Injection Elbow and Heat-Exchanger

It makes me grateful I don’t have the issue in the first article mind you!! The interface between the exchanger and the manifold is fine thank heavens.

Re reading the article above it put the reason for the salt water being there spray back due to the salt water inlet being partially blocked up (mine was), so this could be a more plausible reason as to the water reaching that point.

Stop attacking it! The water passage is quite close to the flange there! If you machine it you will break through. The issue with these engines is that when the elbow blocks, when the engine stops, the water migrates back in to the manifold and then attacks the valve seats. Hence the lack of compression. Its head off time and valve grinding time. Be careful!Thread revivial... Investigating a salt water leak from my MD2020D (about a teaspoon of water soon after startup, and no more after that) I found it was wet around the exhaust elbow (S/S fabricated item from Keypart) and the lower RHS stud nut was very rusty. Removed the elbow and found the weld between the tube and the flange had cracked. That was minor compared to this:

View attachment 151578

After removing the studs and brushing off the loose bits:

View attachment 151579

The yellow circle approximates to where the hole in the gasket would be.

View attachment 151580

The notch is where I've attacked it with a file to find some solid metal.

I think this is may be salvageable by milling around 7-8mm off and making a 7-8mm spacer to go between the housing and the elbow. If the spacer were aluminium and had a slot to match that in the housing rather than a circular hole then that would give some protection to the face of the housing, and the spacer could be considered sacrificial in and replaced when it has corroded sufficiently.

However... despite that fact that the engine was running fine I find that turning it over by hand there is good compression on #1, some compression on #2 (hissing of escaping air), and nothing discernable on #3. I've been told that #3 is prone to this being so close to the exhaust, the valves can rust. So next job is head off.

It's a bit like renovating an old house - one minor repair and bit-by-bit you take the whole thing to pieces.

Ok, there is a vid floating around the net of a German guy cutting big lumps out of an MD22 manifold and tig welding fresh aluminium in. If you are confident of your abilities this could be done to save brewsters.Yes I know there isn't much meat there, but there does appear to be enough as long as the metal is sound. Nothing lost if it breaks through as it is scrap as it stands. A new heat exchanger housing is north of £1200... I have the option of a complete used engine which needs a bottom end rebuild but apparently has a good head, heat exchanger & elbow for not much more than half the price of a new heat exchanger housing (includes alternator, starter motor etc.) so that might be a more economical route and leave me with some useful spares - subject to verifying the condition of the head/heat exchanger housing/elbow of course. Anyway, next job is to whip the head off and see what I find.

Alternative approach to the corroded HE problem (not for me thanks) - found on EBay:

View attachment 151583