stylo

New Member

In preparation for replacing my stern gland I've read with interest many related articles and seen the informative cox engineering site.

My situation on a MG335 is that there is little space (15mm) at the engine/gearbox side of the stern gland for removal of the insertion tool though I expect with the wiggling we'll manage it. Alternatives seem if anything to be longer than the Volvo option so given the space restrictions will be best to go with that (25mm shaft).

Another consideration is that I suspect the current stern gland has been there for 10+ years so anticipate some challenges in removal of the shaft. Any tips on this appreciated for this!

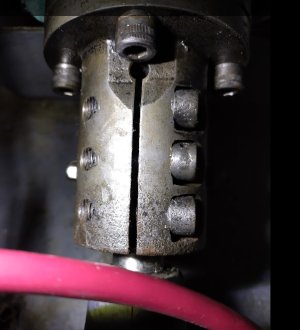

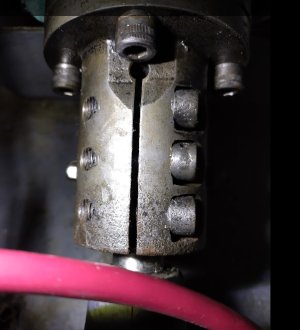

I think that I need to remove the 6 bolts going through the collar type connection and also the central bolt that I think goes through the shaft itself. Does the shaft then get pulled out maybe with some gentle prising apart of the collar along the groove (have enough clearance for prop to move backwards) or is it necessary also to remove that collar with the additional 4 bolts and separate that from the gearbox side collar?

My situation on a MG335 is that there is little space (15mm) at the engine/gearbox side of the stern gland for removal of the insertion tool though I expect with the wiggling we'll manage it. Alternatives seem if anything to be longer than the Volvo option so given the space restrictions will be best to go with that (25mm shaft).

Another consideration is that I suspect the current stern gland has been there for 10+ years so anticipate some challenges in removal of the shaft. Any tips on this appreciated for this!

I think that I need to remove the 6 bolts going through the collar type connection and also the central bolt that I think goes through the shaft itself. Does the shaft then get pulled out maybe with some gentle prising apart of the collar along the groove (have enough clearance for prop to move backwards) or is it necessary also to remove that collar with the additional 4 bolts and separate that from the gearbox side collar?