Keith-i

Well-Known Member

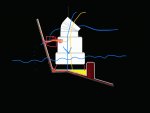

Vas, I fitted a Centek waterlock silencer a while back and iirc the inlet is halfway up the side and the outlet is off the top. Quite what goes on inside I have no idea but I may have a manufacturers diagram somewhere so I’ll take a look for it. I bought a length of 6” grp exhaust tube from asap supplies. I still have a metre spare but I’m not sure of the practicalities of shipping it to you if it would be of use.