vas

Well-known member

hello all,

following work carried out on salon floor to improve sound insulation as discussed here:

http://www.ybw.com/forums/showthread.php?497788-sound-insulation-under-the-salon-carpet

and a general discussion on silencers:

http://www.ybw.com/forums/showthrea...-the-aft-deck-at-D-speeds-any-cheap-solutions

I think it's time to go ahead with something that will drastically lower the noise on aft deck at slow cruising (which is what I mostly do anyway...)

Bearing in mind I'm on 5inch (127mm if you wish) exhaust pipes costs for "dustbins" are much more than what I'm comfortable paying (Vetus is over 500 each side, Halyard and Centek are over a grand each side!) and unfortunately CoastalRides only has 4inch bins. I sketched some custom made ones to fit the available space. These turn out rather large (keeping volume in line with Vetus suggestions and the respective sizes of the others) taking a largish chunk of my e/r behind the gboxes and to the side of the hull. Further it's going to be a rather laborious process using a material that I really don't like, glassfibre.

Now, last week on the boatyard I had a look at an Azimuth 50something with CAT engines and underwater exhausts.

It's just a vertical pipe about an inch larger than the actual exhaust pipe going up half a metre and then reduced to the flexhose size for another 20odd cm. All that sits 1/3 from the side chine compared to mid of boat/keel area.

In my case that means half a metre of 6inch dia grp exhaust hose followed by a 45degree elbow of 5inch.

The contraption will fit in the frame behind the gbox leaving enough space to pull a gbox back 100 or more mm to disconnect and lift it off if need arises (touch wood not keen on doing it again on stbrd engine!). I'll clear the waterline by a safe 20cm just to be safe...

Then on the elbow I'll fabricate a 1.5inch (up to 2.0 that's to be discussed) take off that will lead to the normal existing outlet. The tell tale thing that relieves backpressure.

something like this ebay ad

I'll also get a corner made out of 12mm ply bolted and epoxied to the outside engine bearer and the frame aft of the gbox to secure/epoxy the pipe to and make sure it wont be knocked off somehow and flood the e/r (cannot imagine how but better be safe on that!). Mind doing all that means that the flexhose will only be a metre long on port and 1.3 on stbrd clearing up the path to the outside of the engines for servicing and general access.

Outlet will be vertical to the hull deadrise (or could be just vertical to sea level-not sure what's best) and offset to propshaft by 300mm (centre of the 6inch hole to shaft).

Enough of a description Q time:

A. any smart calc thing to establish if the bypass should be 1.5, 2.0 or more inch in dia?

B. what are the chances of this bypass being noisy and I end up adding a silencer to it as well

C. prop aeration and all that, do they make any difference or no sense discussing them (7-9kn) or even at 19kn?

D. do I need to create a "spoiler" thing in the front side of the hole to hull joint in order to avoid backpressure on things exiting?

If I go ahead, I really only need:

An 90deg elbow that I'll cut in half to get my two 45deg:

https://www.ebay.co.uk/itm/Centek-M...ass-Elbow-5-x-90-Degrees-1200175/223181045324

and a length of six inch grp pipe like this:

https://www.ebay.co.uk/itm/Centek-F...32-Long-1641979-Marine-Vernatube/273673832640

I'll do the reduction mating and epoxying myself, it's a small enough job I can handle

my main problem other than a confirmation that this should work, is that I could only find the materials I need in the US, not keen on shipping a 3m pipe from there tbh nor am I sure that the seller will be happy cutting in two (or three...) before shipping

nor am I sure that the seller will be happy cutting in two (or three...) before shipping

Any comments/ideas gratefully accepted as always

cheers

V.

following work carried out on salon floor to improve sound insulation as discussed here:

http://www.ybw.com/forums/showthread.php?497788-sound-insulation-under-the-salon-carpet

and a general discussion on silencers:

http://www.ybw.com/forums/showthrea...-the-aft-deck-at-D-speeds-any-cheap-solutions

I think it's time to go ahead with something that will drastically lower the noise on aft deck at slow cruising (which is what I mostly do anyway...)

Bearing in mind I'm on 5inch (127mm if you wish) exhaust pipes costs for "dustbins" are much more than what I'm comfortable paying (Vetus is over 500 each side, Halyard and Centek are over a grand each side!) and unfortunately CoastalRides only has 4inch bins. I sketched some custom made ones to fit the available space. These turn out rather large (keeping volume in line with Vetus suggestions and the respective sizes of the others) taking a largish chunk of my e/r behind the gboxes and to the side of the hull. Further it's going to be a rather laborious process using a material that I really don't like, glassfibre.

Now, last week on the boatyard I had a look at an Azimuth 50something with CAT engines and underwater exhausts.

It's just a vertical pipe about an inch larger than the actual exhaust pipe going up half a metre and then reduced to the flexhose size for another 20odd cm. All that sits 1/3 from the side chine compared to mid of boat/keel area.

In my case that means half a metre of 6inch dia grp exhaust hose followed by a 45degree elbow of 5inch.

The contraption will fit in the frame behind the gbox leaving enough space to pull a gbox back 100 or more mm to disconnect and lift it off if need arises (touch wood not keen on doing it again on stbrd engine!). I'll clear the waterline by a safe 20cm just to be safe...

Then on the elbow I'll fabricate a 1.5inch (up to 2.0 that's to be discussed) take off that will lead to the normal existing outlet. The tell tale thing that relieves backpressure.

something like this ebay ad

I'll also get a corner made out of 12mm ply bolted and epoxied to the outside engine bearer and the frame aft of the gbox to secure/epoxy the pipe to and make sure it wont be knocked off somehow and flood the e/r (cannot imagine how but better be safe on that!). Mind doing all that means that the flexhose will only be a metre long on port and 1.3 on stbrd clearing up the path to the outside of the engines for servicing and general access.

Outlet will be vertical to the hull deadrise (or could be just vertical to sea level-not sure what's best) and offset to propshaft by 300mm (centre of the 6inch hole to shaft).

Enough of a description Q time:

A. any smart calc thing to establish if the bypass should be 1.5, 2.0 or more inch in dia?

B. what are the chances of this bypass being noisy and I end up adding a silencer to it as well

C. prop aeration and all that, do they make any difference or no sense discussing them (7-9kn) or even at 19kn?

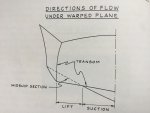

D. do I need to create a "spoiler" thing in the front side of the hole to hull joint in order to avoid backpressure on things exiting?

If I go ahead, I really only need:

An 90deg elbow that I'll cut in half to get my two 45deg:

https://www.ebay.co.uk/itm/Centek-M...ass-Elbow-5-x-90-Degrees-1200175/223181045324

and a length of six inch grp pipe like this:

https://www.ebay.co.uk/itm/Centek-F...32-Long-1641979-Marine-Vernatube/273673832640

I'll do the reduction mating and epoxying myself, it's a small enough job I can handle

my main problem other than a confirmation that this should work, is that I could only find the materials I need in the US, not keen on shipping a 3m pipe from there tbh

Any comments/ideas gratefully accepted as always

cheers

V.