Skip 52

Member

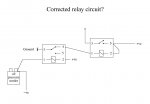

I have a very strange (or at least, so it seems to me) wiring system fitted to the Nanni diesel/ Lewmar bow thruster setup in my 2004 Beneteau motor boat. There are two relays. The first of these is literally hanging off its wires toward the back of the engine. This first relay's activator is connected to the main starter motor +ve cable and to one of the terminals on the oil pressure sender, which seems to be connected to ground (this is what really puzzles me, why connect it to the oil pressure sender?). Thus, immediately when the power is on, this activates the switch… which connects a cable from the main ground on the engine… to post 1 of the activator on the second relay. I'm not impressed with the wire used here, by the way - it's a normal AC flex with the other two wires, the brown and the yellow/green, simply snipped off. So it's not exactly a highly professional job!

The second relay is on the bulkhead in front of the engine, about six feet away from the first one. It takes a +ve feed from the bow thruster fuse (via a smaller inline fuse) to both the activator (post 2) and the switch (post 5). Which then feeds a +ve current to two other wires which disappear into a harness Thus this second relay feeds +ve current immediately the power is on.

To sum it up, power on = both relays activated.

So, why have two relays at all? Surely I would get the same effect by simply connecting the +ve feed from the bow thruster fuse directly to the two other wires into the harness - unless I am missing something that the oil pressure sender is, or should be doing? The oil pressure gauge works fine.

The only reason I can think of for these relays is that it was a failed attempt to stop the bow thruster from being operated when the engine isn't running?

I am in no way an electrician and, although I hate to see a relay hanging off the back of the engine from a domestic cable, I am reluctant to mess with it in case it's simply a matter of my not understanding. Any suggestions or advice would be most gratefully received!

The second relay is on the bulkhead in front of the engine, about six feet away from the first one. It takes a +ve feed from the bow thruster fuse (via a smaller inline fuse) to both the activator (post 2) and the switch (post 5). Which then feeds a +ve current to two other wires which disappear into a harness Thus this second relay feeds +ve current immediately the power is on.

To sum it up, power on = both relays activated.

So, why have two relays at all? Surely I would get the same effect by simply connecting the +ve feed from the bow thruster fuse directly to the two other wires into the harness - unless I am missing something that the oil pressure sender is, or should be doing? The oil pressure gauge works fine.

The only reason I can think of for these relays is that it was a failed attempt to stop the bow thruster from being operated when the engine isn't running?

I am in no way an electrician and, although I hate to see a relay hanging off the back of the engine from a domestic cable, I am reluctant to mess with it in case it's simply a matter of my not understanding. Any suggestions or advice would be most gratefully received!