Matwill

Well-Known Member

Hi Guys,

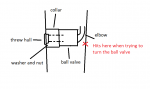

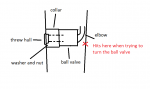

Im installing a tru design through hull however i have an issue with installation space, i can install the outlet elbow or the ball valve onto the through hull, but not both at the same time, its out by about 5mm on the elbow when it turns on the aft side.

I was thinking i could 5200 the nut and washer in place, then screw in the through hull directly into the ball valve from the outside of the hull, the issue i see would be a radial squeeze of the 5200 rather then just doing it normally which would be to use the nut to pull it

Would my idea work? What do people think.

Im installing a tru design through hull however i have an issue with installation space, i can install the outlet elbow or the ball valve onto the through hull, but not both at the same time, its out by about 5mm on the elbow when it turns on the aft side.

I was thinking i could 5200 the nut and washer in place, then screw in the through hull directly into the ball valve from the outside of the hull, the issue i see would be a radial squeeze of the 5200 rather then just doing it normally which would be to use the nut to pull it

Would my idea work? What do people think.