coopec

N/A

I have an Airex sandwich hull and needed to install thru-hulls for the toilet. I drilled the holes in the hull, dug out the Airex, laid glass over the the hole to stop water getting into the core.

I wasn't too happy with the result so I filled the hole with epoxy bog and then laid X3 layers of glass cloth over the bog. I then re-drilled the hole and now I am quite happy with the result (on a critical part of the construction)

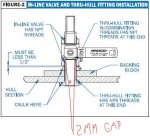

But now the hull is fairly thick and the ball valve won't quite bottom-out on the through hull skin fitting. I don't know much about NPT fittings but if I use some Teflon tape that should be perfectly OK shouldn't it? (Alternatively I could take up the gap with a nylon washer?)

The notation on the drawing MUST BE LESS THAN 1/2" is to ensure a sufficient number of threads on the skin fitting are used? (These under-water fittings worry me) ☹

I wasn't too happy with the result so I filled the hole with epoxy bog and then laid X3 layers of glass cloth over the bog. I then re-drilled the hole and now I am quite happy with the result (on a critical part of the construction)

But now the hull is fairly thick and the ball valve won't quite bottom-out on the through hull skin fitting. I don't know much about NPT fittings but if I use some Teflon tape that should be perfectly OK shouldn't it? (Alternatively I could take up the gap with a nylon washer?)

The notation on the drawing MUST BE LESS THAN 1/2" is to ensure a sufficient number of threads on the skin fitting are used? (These under-water fittings worry me) ☹