ritchyp

Member

Hi,

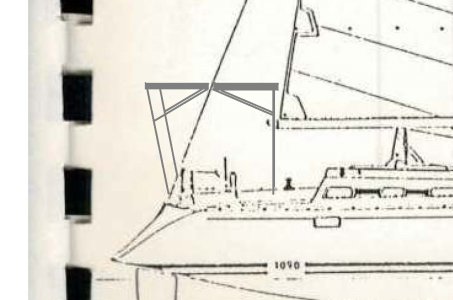

I will be moving aboard in the Summer and heading to the Med. I am building a solar arch (and shaded area as my yacht's cockpit configuration is no good for a Bimni in any case)

It will be slightly curved and I will be using six 130 Watt flexible PV panels to save on weight. These ones have a better efficiency rating than most rigid 35mm panels weighing 10KGs. Inexpensive too.

Anyway that is not something I wish to debate

I have been looking at Subtrates or types of board to stick them on. I was hoping to find something thinner and lighter and stronger than marine ply. GRP sheeting was a thought but The want £500 a sheet!! the cheapest I found after hunting around online for an hour, was £360 for a sheet of GRP 2.4m x 1.2m x 13mm. I need 2 sheets with a bit of waste. The area is 2.2m wide and a similar length. MDF was suggested but that is not durable enough and doesn't do well in the wet or heat. It needs to be strong so that a 50 or 60 knot gust of wind would not rip it it off its brackets. Ideas...?

Cheers

I will be moving aboard in the Summer and heading to the Med. I am building a solar arch (and shaded area as my yacht's cockpit configuration is no good for a Bimni in any case)

It will be slightly curved and I will be using six 130 Watt flexible PV panels to save on weight. These ones have a better efficiency rating than most rigid 35mm panels weighing 10KGs. Inexpensive too.

Anyway that is not something I wish to debate

I have been looking at Subtrates or types of board to stick them on. I was hoping to find something thinner and lighter and stronger than marine ply. GRP sheeting was a thought but The want £500 a sheet!! the cheapest I found after hunting around online for an hour, was £360 for a sheet of GRP 2.4m x 1.2m x 13mm. I need 2 sheets with a bit of waste. The area is 2.2m wide and a similar length. MDF was suggested but that is not durable enough and doesn't do well in the wet or heat. It needs to be strong so that a 50 or 60 knot gust of wind would not rip it it off its brackets. Ideas...?

Cheers