emnick

Well-Known Member

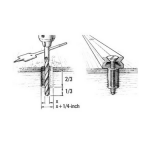

I will be removing the stern tube on our boat soon. Last time I had it out the threads (see pic) where the stern tube bolts to the small skeg were not so good. I think when I take it out again they will need re tapping. Its a solid block of fibreglass. What do you think the best way of re threading, The stern tube holes won't allow a bigger bolt. Is it feasible to fill the hole with epoxy or something similar/ better ??? drill it and re tapp or is there some sort of "helicoil" that could be used.

Thanks for any help

PS sorry about poor pic quality

Thanks for any help

PS sorry about poor pic quality