BobnLesley

Well-Known Member

Can it occur due to a 12V DC leakage, or just with 100/220V AC shore power?

I ask because we've got a couple of problems that could be explained by stray current/earth corrosion, but whilst the the boat's got a shore power system, it's not been 'plugged-in' whilst afloat in more than seven years, indeed it's only been plugged-in whilst ashore about two or three times. Nor has the boat spent long periods moored/anchored amongst other boats which're plugged into shore power; no doubt more than a few run generators, but again, we might've been anchored close to such for days, not weeks or months at a time.

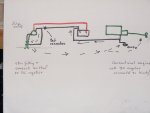

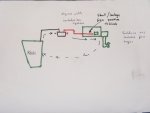

If it is possible to corrode from the 12V DC system, then how do I go about tracking/isolating/curing the problem?

If it is possible via a 12 volt

I ask because we've got a couple of problems that could be explained by stray current/earth corrosion, but whilst the the boat's got a shore power system, it's not been 'plugged-in' whilst afloat in more than seven years, indeed it's only been plugged-in whilst ashore about two or three times. Nor has the boat spent long periods moored/anchored amongst other boats which're plugged into shore power; no doubt more than a few run generators, but again, we might've been anchored close to such for days, not weeks or months at a time.

If it is possible to corrode from the 12V DC system, then how do I go about tracking/isolating/curing the problem?

If it is possible via a 12 volt