Tim Good

Well-Known Member

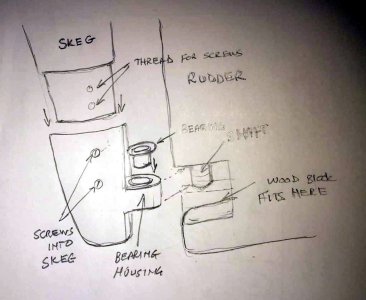

I’ve removed my rudder and assessing the bearings which are in good condition after 25 years and the tolerances are still acceptable. Shaft is 2 inch with 0.22mm bearing clearance.

However when I look down into the shoe I see only a bearing on the outside without a base.

When full inserted, as though the weight of the skeg is resting on the shoe, as it should, then the stainless rudder shaft is simply sitting on what appears to be a stainless plate. Is that right?

Or should there be a delrin base to the bearing? Or is that stainless base some kind of stainless thrust bearing that I can see fully?

However when I look down into the shoe I see only a bearing on the outside without a base.

When full inserted, as though the weight of the skeg is resting on the shoe, as it should, then the stainless rudder shaft is simply sitting on what appears to be a stainless plate. Is that right?

Or should there be a delrin base to the bearing? Or is that stainless base some kind of stainless thrust bearing that I can see fully?