Supertramp

Well-Known Member

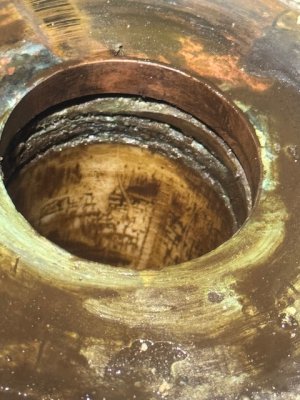

I assume that is the emergency steering and the shaft simply passes up through the roller bearing without reaching a limit.

I think yours is similar to mine. It has some small vertical "float" and is restricted by the skeg (downwards limit) and the rudder meeting the hull bearing or perhaps in your case the top bearing. The movement will be minimal but present. I have never been aware of any vertical movement in the shaft while in rough weather. My rudder is probably smaller than yours and weighs about 50 kg and I suspect sits supported by the skeg In my case. I don't see a problem with this - the underwater bearings are delrin/metal and metal/metal in my case with the third upper bearing another delrin/metal but with a grease point to stop any water passing.

I think yours is similar to mine. It has some small vertical "float" and is restricted by the skeg (downwards limit) and the rudder meeting the hull bearing or perhaps in your case the top bearing. The movement will be minimal but present. I have never been aware of any vertical movement in the shaft while in rough weather. My rudder is probably smaller than yours and weighs about 50 kg and I suspect sits supported by the skeg In my case. I don't see a problem with this - the underwater bearings are delrin/metal and metal/metal in my case with the third upper bearing another delrin/metal but with a grease point to stop any water passing.