simonfraser

Well-Known Member

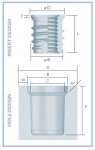

M3 x 5.2

the external thread measures 4.7mm

all sorts of insert guidance on google, but not clear to me

its going in aluminium

what drill size to use for the hole ?

and screwing it in, do i put an M3 bolt in with a nut at the end and use that as an insertion tool ?

tnx

the external thread measures 4.7mm

all sorts of insert guidance on google, but not clear to me

its going in aluminium

what drill size to use for the hole ?

and screwing it in, do i put an M3 bolt in with a nut at the end and use that as an insertion tool ?

tnx