glynsue

New member

Seafarer 501 Echo Sounder:

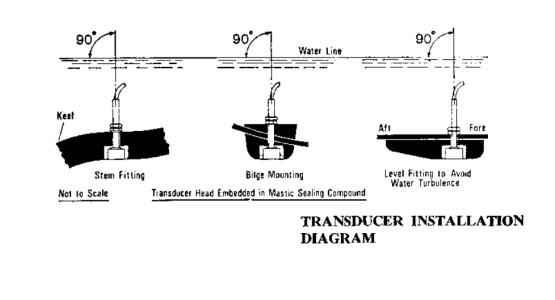

I want to install the above in my Buchanan 24ft.Wooden Boatand I would like to find a copy of the

Installation And Operating Instructions -

will the transducer supplied work with the through hull bronze fittingcurrently the fitting appears to be capped off.

Has anyone got a manual I could copy please