Brent Swain

N/A

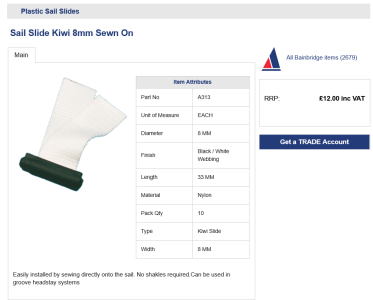

A luff tape or luff rope supports the sail for it's entire length, drastically reducing the load on the halyard, and the compression load on the furler. Hanks and slides point load it, drastically increasing the loads. Friends have overcome this, to some extent, by putting in grommets and far more slides between the existing ones. Grommet dies are cheap and easy to use.