PabloPicasso

Well-Known Member

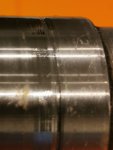

I tackled the job of removing my 120s saildrive propshaft this afternoon (the oil was a milky brown colour, likely inducting water ingress).

It took a little while to release it from its housing with careful, but persistent, tapping with a mallet. I fitted the bronze capture nut that holds the prop on, and a wooden wedge to aim the blows. Once a gap had appeared I used a large flat bladed screwdriver to gently prize the peices apart, working evenly around the hub.

Now, before I fit the new seals and put it all back together, is this "scoring" that needs to be "sleeved", or is still serviceable?

Many thanks.

It took a little while to release it from its housing with careful, but persistent, tapping with a mallet. I fitted the bronze capture nut that holds the prop on, and a wooden wedge to aim the blows. Once a gap had appeared I used a large flat bladed screwdriver to gently prize the peices apart, working evenly around the hub.

Now, before I fit the new seals and put it all back together, is this "scoring" that needs to be "sleeved", or is still serviceable?

Many thanks.

Attachments

Last edited: