rogerthebodger

Well-Known Member

Hi Roger.

How did you keep the ball bearings in place in the Delrin /Plastic sheaves?

Locktite or some other product?

gary

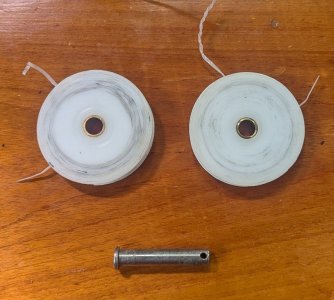

A press fit mainly but I used washers on each side of the pully to keep it in the center of the gap in the mast head filling located by the side plates that guide the halyard.

If memory serves I used 2 bearings in each sheave that in my case was the same width of the sheave.

Top pully was aliminium but the bottom was made from vesconite