Kelpie

Well-Known Member

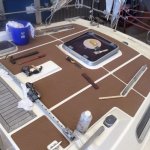

We're viewing a boat that has a teak deck that is at the end of its life. This fact is reflected in the price to some extent, but it's still a daunting prospect.

I've been watching the excellent videos from Mads 'Sail life' on Youtube, and I would want to copy what he has done- strip off all the deck fittings, then the teak, then find the areas of damaged core and cut these out and replace, and finally apply suitable primers/undercoats and then finish with Kiwigrip.

I would be looking to do this myself, so what I really need to get an idea of is the costs for the materials. The boat is a 40ft centre cockpit Westerly. It's a pretty big deck area to be fixing! I don't yet know what state the core is in, but I guess I have to assume the worst and budget to replace all of it.

Is there a better replacement material than balsa? How much more would this cost?

What might I be needing in the way of epoxy- it seems quite hard to estimate.

My very rough guesstimate is that this is likely a £2-£3k job, but a lot depends on how much core needs removed, and what else I uncover along the way.

Does this sound in the right ballpark?

I've been watching the excellent videos from Mads 'Sail life' on Youtube, and I would want to copy what he has done- strip off all the deck fittings, then the teak, then find the areas of damaged core and cut these out and replace, and finally apply suitable primers/undercoats and then finish with Kiwigrip.

I would be looking to do this myself, so what I really need to get an idea of is the costs for the materials. The boat is a 40ft centre cockpit Westerly. It's a pretty big deck area to be fixing! I don't yet know what state the core is in, but I guess I have to assume the worst and budget to replace all of it.

Is there a better replacement material than balsa? How much more would this cost?

What might I be needing in the way of epoxy- it seems quite hard to estimate.

My very rough guesstimate is that this is likely a £2-£3k job, but a lot depends on how much core needs removed, and what else I uncover along the way.

Does this sound in the right ballpark?