aidancoughlan

Well-Known Member

Following on from another recent thread ....

http://www.ybw.com/forums/showthrea...is-sound-from-alternator-area-alternator-belt

... I've tried to replace the belt with a cogged belt, but struggled. The fit is *really* tight. I've loosened the bolt at the foot of the alternator (on which it pivots), and the bolt on the alternator arm (on which it moves in/out), but there is no way I can push the alternator close enough to the engine to allow the belt to fit around the last pulley. There is a rubber pipe just behind the alternator which is preventing it going in the last half centimetre on the adjustment arm.

I've also tried removing the alternator completely from it's "footrest", then placing the belt around the alternator pulley (which is possible with a little difficulty), but the angles and the space is such that getting the alternator back into the position where it's "foot" rests so I can through-bolt it on again is tricky - I've not been able to achieve it by and, and I'm reluctant to resort to a hammer.

The alternator is a Hitachi L180-03C 80amp which comes standard on those engines.

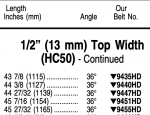

I've had this problem before when the boat was located a long way from home , and I and resorted to an on-site mechanic to replace the belt - they elected to use a smooth belt rather than the Mitshubishi toothed belt I had as spare on board, I wonder if this was the reason. However, french marine (where I got the belt) assured me that this is the right belt.

I've attached a couple of videos here, hopefully it will be obvious what I mean.

Is this level of difficult in replacing a belt normal, or is there something amiss ?

http://www.ybw.com/forums/showthrea...is-sound-from-alternator-area-alternator-belt

... I've tried to replace the belt with a cogged belt, but struggled. The fit is *really* tight. I've loosened the bolt at the foot of the alternator (on which it pivots), and the bolt on the alternator arm (on which it moves in/out), but there is no way I can push the alternator close enough to the engine to allow the belt to fit around the last pulley. There is a rubber pipe just behind the alternator which is preventing it going in the last half centimetre on the adjustment arm.

I've also tried removing the alternator completely from it's "footrest", then placing the belt around the alternator pulley (which is possible with a little difficulty), but the angles and the space is such that getting the alternator back into the position where it's "foot" rests so I can through-bolt it on again is tricky - I've not been able to achieve it by and, and I'm reluctant to resort to a hammer.

The alternator is a Hitachi L180-03C 80amp which comes standard on those engines.

I've had this problem before when the boat was located a long way from home , and I and resorted to an on-site mechanic to replace the belt - they elected to use a smooth belt rather than the Mitshubishi toothed belt I had as spare on board, I wonder if this was the reason. However, french marine (where I got the belt) assured me that this is the right belt.

I've attached a couple of videos here, hopefully it will be obvious what I mean.

Is this level of difficult in replacing a belt normal, or is there something amiss ?