tean

Member

Helo Forum. I have an issue with a 2000 vintage Nanni 14hp, in that it won't heat up to the correct temperature. The fact that the manual that came with the boat has the thermostat cover highlighted and the thermostat part number written in the margin would seem to indicate the previous owner had some issues too.

So I removed the stat cover on the heat exchanger (no mean feat as it's buried under the exhaust elbow which was of course corroded into place) and found that it was assembled incorrctly inside. The thermostat and its retaining spring were the wrong way round. Confident that this was the problem I re-assembled correctly and ran the engine. But there was no improvement: the temperature guage grudgingly made it to about 50 and I could comfortably dunk my finger in the water under the filler cap on the heat exchanger after half an hour of loaded running.

So I splashed out the painful sum of forty quid for a new stat and found it to be slightly longer in the body than the old one. I couldn't really see what difference this would make but put the new stat in and ran the engine under a good load for a while. Still no improvement.

So now I'm confused. It seems the engine can happily cool itself without the stat opening. Now I consult the oracle of YBW and find this old post from 2009,

http://www.ybw.com/forums/showthread.php?187251-Kubota-thermostats&highlight=nanni+thermostat

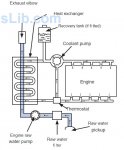

which seems to say this is a design issue that occurs when the raw water is too cold. Well I am running the engine in fresh river water in February. The suggested fix is to fit a seperate thermostat in the Kubota block.

So here's my question:

The Nanni design seems to be done to ensure cooling water circulates through the exhaust manifold even when the stat is closed and the engine block cool. If I fit another stat in the block then it will shut off the circulation through the manifold until the block heats up and the stat opens. Since the exhaust manifold will heat up much quicker, will it overheat when the stat is closed? Should I perhaps drill a hole in the new stat to allow a little water to flow? Anyone else had this issue? Am I losing it and missing something obvious?

Thanks in advance for any suggestions.

So I removed the stat cover on the heat exchanger (no mean feat as it's buried under the exhaust elbow which was of course corroded into place) and found that it was assembled incorrctly inside. The thermostat and its retaining spring were the wrong way round. Confident that this was the problem I re-assembled correctly and ran the engine. But there was no improvement: the temperature guage grudgingly made it to about 50 and I could comfortably dunk my finger in the water under the filler cap on the heat exchanger after half an hour of loaded running.

So I splashed out the painful sum of forty quid for a new stat and found it to be slightly longer in the body than the old one. I couldn't really see what difference this would make but put the new stat in and ran the engine under a good load for a while. Still no improvement.

So now I'm confused. It seems the engine can happily cool itself without the stat opening. Now I consult the oracle of YBW and find this old post from 2009,

http://www.ybw.com/forums/showthread.php?187251-Kubota-thermostats&highlight=nanni+thermostat

which seems to say this is a design issue that occurs when the raw water is too cold. Well I am running the engine in fresh river water in February. The suggested fix is to fit a seperate thermostat in the Kubota block.

So here's my question:

The Nanni design seems to be done to ensure cooling water circulates through the exhaust manifold even when the stat is closed and the engine block cool. If I fit another stat in the block then it will shut off the circulation through the manifold until the block heats up and the stat opens. Since the exhaust manifold will heat up much quicker, will it overheat when the stat is closed? Should I perhaps drill a hole in the new stat to allow a little water to flow? Anyone else had this issue? Am I losing it and missing something obvious?

Thanks in advance for any suggestions.