Refueler

Well-Known Member

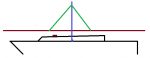

Guy I knew had some short rod bridles made up ... he would clip to toerail ... top apex to cap shrouds ... giving him change of anchor point of the cap shrouds. With care they assisted keeping mast straight.

Another guy I knew - used rolling hitch lines to cap shrouds, led forward to set higher point of pivot on shrouds.

So far my A frame seems to work ok without .... just need to see if I can use for the horizontal work.

The idea of rolling on cabin top is not really viable as my pushpit / pulpit are much higher and I usually have a sprayhood ... even the hood down would be an obstruction.

Another guy I knew - used rolling hitch lines to cap shrouds, led forward to set higher point of pivot on shrouds.

So far my A frame seems to work ok without .... just need to see if I can use for the horizontal work.

The idea of rolling on cabin top is not really viable as my pushpit / pulpit are much higher and I usually have a sprayhood ... even the hood down would be an obstruction.