Akestor

Well-Known Member

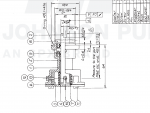

It's a Johnson pump without bearings, the impeller shaft goes through the oil and water seals directly on the camshaft edge. The water seal lasted 90 hours only and luckily there is no oil contamination as i spotted the leak at the weep hole soon enough, and hope the oil seal is still ok. As i had another failure last spring with water getting into the crankcase i am checking the pump very often. I am sure i am installing the seals correctly but with the absence of bearing, it seems that all the shaft movement is loaded on the seals making them fail quickly.

I think this is a very weak link and the engine can fail when i need it...

-Would a new pump with a ball bearing holding the shaft last more hours before seals replacement?

-What about installing a belt-driven pump on the front of the engine? I would have peace of mind knowing that the sea won't get in the crankcase...

I think this is a very weak link and the engine can fail when i need it...

-Would a new pump with a ball bearing holding the shaft last more hours before seals replacement?

-What about installing a belt-driven pump on the front of the engine? I would have peace of mind knowing that the sea won't get in the crankcase...