Praxinoscope

Well-Known Member

Kicking myself! I’m blaming Covid (I don’ make mistakes). The winter season before we got locked down, we dropped the mast on my Sadler 25 so it was 18 months to 2 years before we eventually got the mast back up, since then I have had problems adjusting the rake and getting rid of a slight curve to stern at spreader level.

Cap shrouds are perfect, tightened to about 15% port and stbd, backstay about 12%, lower shrouds are both about 12% and have provided the lateral adjustment needed to straighten mast laterally, but still can’t get rake correct and lose the slight curve at spreader height.

This is where I apply for the Darwin award, boat has a Plastimo 608-1 furling system which is totally new to me (my last boat was hank on sails) unfortunately I find the Plastimo installation instructions a bit vague at some points and the relationship between the forestay and the Palstimo chainplates a bit lacking.

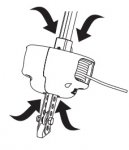

Hving looked very closely at the chainplate unit (photo’s attached) I think maybe we missed a second bolt when putting the mast up and assumed that the forestay and the chainplate are bolted through the same hole (photo 1:2), I now think I am wrong and looking at the chainplate it looks as if before the mast was dropped and I bought the boat the forestay was bolted through the holes further up indictaed by an arrow in photo 2:2, there are signs of a bolt previously fitted at that point.

Am I right in thinking that the plastic chain plates are fastened to the stemmed roller and the forestay fixed further up thus allowing the rake and reaction in mast bend I have been trying to cure?

Any advice on this much appreciated.

1:2

1:2  2:2

2:2

Cap shrouds are perfect, tightened to about 15% port and stbd, backstay about 12%, lower shrouds are both about 12% and have provided the lateral adjustment needed to straighten mast laterally, but still can’t get rake correct and lose the slight curve at spreader height.

This is where I apply for the Darwin award, boat has a Plastimo 608-1 furling system which is totally new to me (my last boat was hank on sails) unfortunately I find the Plastimo installation instructions a bit vague at some points and the relationship between the forestay and the Palstimo chainplates a bit lacking.

Hving looked very closely at the chainplate unit (photo’s attached) I think maybe we missed a second bolt when putting the mast up and assumed that the forestay and the chainplate are bolted through the same hole (photo 1:2), I now think I am wrong and looking at the chainplate it looks as if before the mast was dropped and I bought the boat the forestay was bolted through the holes further up indictaed by an arrow in photo 2:2, there are signs of a bolt previously fitted at that point.

Am I right in thinking that the plastic chain plates are fastened to the stemmed roller and the forestay fixed further up thus allowing the rake and reaction in mast bend I have been trying to cure?

Any advice on this much appreciated.

1:2

1:2  2:2

2:2