john_morris_uk

Well-Known Member

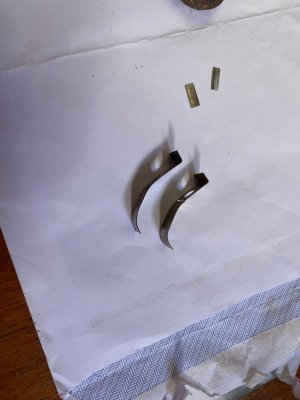

An update;

I’ve been in touch with Spring Steel Strip to Hobbyists and Model Engineers and unfortunately they say they cannot help. Here’s their reply:

Hi John,

Further to our telecon and your sample.

Unfortunately , we are unable to manufacture your final spring part,

We have tested – your sample.

Hardness = hardness value.

Hv – 430

Tensile hrc rockwell 44.

Width 13 mm wide

Gauge = 0.40 mm .

We can offer 1 sheet of stainless steel spring steel : Grade 301 European 1.4310 tr 380 to 450 range. Spring steel.

1 sheet 1000 mm long x 300 mm wide x 0.40 mm .

Price = £205.00 pounds lump sum plus vat delivered to your house/factory.

Please let me know if this stainless steel is of interest? Or if we can be of further service. We will post your sample back to your Worcestershire Address.

Obviously I’m not paying £200+ for a sheet of s/s so I’m back to square one.

I’ll try other sources. Otherwise if anyone has a few cm’s of 0.4mm spring steel 13mm wide I’ll try tempering forming etc myself. It’s not critical as it’s just got to hold a pawl in place on a ratchet wheel.

I’ve been in touch with Spring Steel Strip to Hobbyists and Model Engineers and unfortunately they say they cannot help. Here’s their reply:

Hi John,

Further to our telecon and your sample.

Unfortunately , we are unable to manufacture your final spring part,

We have tested – your sample.

Hardness = hardness value.

Hv – 430

Tensile hrc rockwell 44.

Width 13 mm wide

Gauge = 0.40 mm .

We can offer 1 sheet of stainless steel spring steel : Grade 301 European 1.4310 tr 380 to 450 range. Spring steel.

1 sheet 1000 mm long x 300 mm wide x 0.40 mm .

Price = £205.00 pounds lump sum plus vat delivered to your house/factory.

Please let me know if this stainless steel is of interest? Or if we can be of further service. We will post your sample back to your Worcestershire Address.

Obviously I’m not paying £200+ for a sheet of s/s so I’m back to square one.

I’ll try other sources. Otherwise if anyone has a few cm’s of 0.4mm spring steel 13mm wide I’ll try tempering forming etc myself. It’s not critical as it’s just got to hold a pawl in place on a ratchet wheel.