Neeves

Well-Known Member

A problem I perceive with tab washers is that they are single use, or the ones from Volvo appear to be. When you fold the tab over you weaker the steel, to release the tab you further weaken the steel. I don't know how many cycles the tab will take but I can believe that if you throw the drive from forward to reverse there will be a point when the tab breaks off (from the change in torque).

I know tab washers have extra tabs but if you replace the prop the same way each time it is inevitable you will use the same tab.

How many carry spare tab washers.

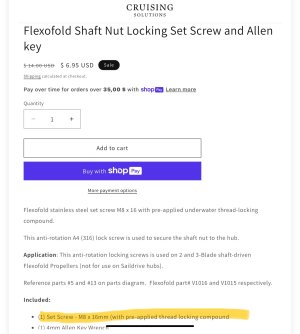

I have a preference for belt and braces and use Loctite as well - where appropriate.

Jonathan

I know tab washers have extra tabs but if you replace the prop the same way each time it is inevitable you will use the same tab.

How many carry spare tab washers.

I have a preference for belt and braces and use Loctite as well - where appropriate.

Jonathan