MagicalArmchair

Well-Known Member

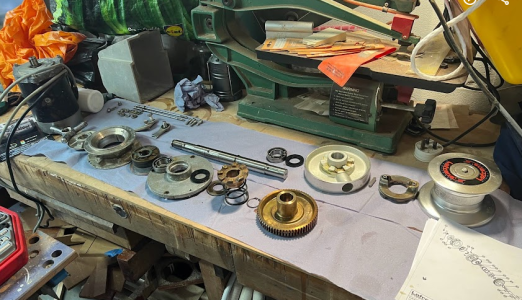

My Cayman 88 1000W windlass has seen no TLC since I purchased the boat over two years ago. I'd love to give it a service - it has worked faultlessly over these two years so deserves it!

I presume I need to top up the below with gear oil until it comes out of the hole?

And then is it a case of taking off the gypsy and greasing the shaft up? (not the clutch cone that I am guessing is inside here!)

Some other elements that concern me is the corrosion of the base seen here, and I see in the post Lofrans winch body corrosion. Mudisox had a similar issue with the base, so it might be a "take it off" job... I might then give it the full once over on the bench at home in that case...

And the electrical contacts on the plug for the controls. Could I put Tef Gel on those contacts? How would I remove that corrosion? Replace that plug?:

I presume I need to top up the below with gear oil until it comes out of the hole?

And then is it a case of taking off the gypsy and greasing the shaft up? (not the clutch cone that I am guessing is inside here!)

Some other elements that concern me is the corrosion of the base seen here, and I see in the post Lofrans winch body corrosion. Mudisox had a similar issue with the base, so it might be a "take it off" job... I might then give it the full once over on the bench at home in that case...

And the electrical contacts on the plug for the controls. Could I put Tef Gel on those contacts? How would I remove that corrosion? Replace that plug?: