merjan

Well-Known Member

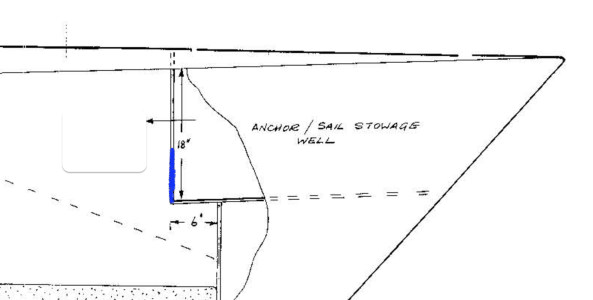

I need a bit of a sanity check about the replacement of a water-damaged forward bulkhead between the chain locker and the forward cabin. I am intending to do this with the boat ashore and the deck-stepped mast on. That means that there is some tension on the forestay I am wondering if the forward part of the hull will flex considerably when I remove the old bulkhead.

The boat is 28' GRP. The chain locker is about 600mm deep below the deck level and 1200mm wide at the bulkhead. Its sole is horizontally tabbed to the inside of the hull.

In an extreme scenario I can imagine the force due to the forestay tension will want to make the hull "open up" outwards (imagine pinching a yogurt tub). However I consider this to be negligeable, and expect the deck and the sole of the chain locker to give the hull enough rigidity whilst I tab in the new bulkhead. Does that make sense to anyone who has an idea about the loads on GRP hulls and the strength thereof? Should I loosen the rig in the process?

Also I'm planning to use CT1 instead of foam. If anyone has any objection to that, I'd like to find that out as well. Thanks in advance!

The boat is 28' GRP. The chain locker is about 600mm deep below the deck level and 1200mm wide at the bulkhead. Its sole is horizontally tabbed to the inside of the hull.

In an extreme scenario I can imagine the force due to the forestay tension will want to make the hull "open up" outwards (imagine pinching a yogurt tub). However I consider this to be negligeable, and expect the deck and the sole of the chain locker to give the hull enough rigidity whilst I tab in the new bulkhead. Does that make sense to anyone who has an idea about the loads on GRP hulls and the strength thereof? Should I loosen the rig in the process?

Also I'm planning to use CT1 instead of foam. If anyone has any objection to that, I'd like to find that out as well. Thanks in advance!