tawhiri

Well-Known Member

Hi all

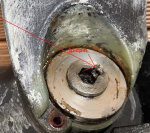

I need to remove the blades of my Kiwiprop SDC to replace the Vectran rope which feathers them in normal operation. It is the two blade model.

I am stuck with removing the split pin through the head of the allen key bolt securing the blade see picture.

I am unable to get behind the blade to release the split pin, and I can only pull it from the top, but is is not moving.

Does anybody have an advice on how to remove this split pin.

Thanks in advance Andrew

I need to remove the blades of my Kiwiprop SDC to replace the Vectran rope which feathers them in normal operation. It is the two blade model.

I am stuck with removing the split pin through the head of the allen key bolt securing the blade see picture.

I am unable to get behind the blade to release the split pin, and I can only pull it from the top, but is is not moving.

Does anybody have an advice on how to remove this split pin.

Thanks in advance Andrew