skippeer

Well-Known Member

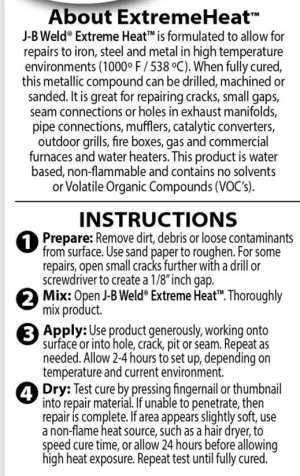

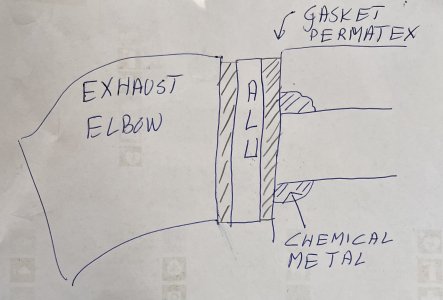

As a temporary solution for the season did I apply "JB Weld Extreme Heat" and used it as any chemical metal paste in a thick layer.

Ones you open and mixed it you need to use it directly, not like 2 components epoxy pastes there you can mix exactly what you need now and save it for next project.

I picked JB Weld Extreme Heat because it is the flange on the exhaust manifold I am trying to refill what has corroded away as a temporary to when the Penta workshop have time to help me with my D2-55 A engine.

After 22 hours in 25 Celcius degrees still soft.

Will be searching for my electrical air heat gun in the boat and use it to stress the process.

What chemical metal paste can cope with high temperatures?

Considering to remove the soft JB Weld paste.

Any other DIY persons able to share experiences?

Ones you open and mixed it you need to use it directly, not like 2 components epoxy pastes there you can mix exactly what you need now and save it for next project.

I picked JB Weld Extreme Heat because it is the flange on the exhaust manifold I am trying to refill what has corroded away as a temporary to when the Penta workshop have time to help me with my D2-55 A engine.

After 22 hours in 25 Celcius degrees still soft.

Will be searching for my electrical air heat gun in the boat and use it to stress the process.

What chemical metal paste can cope with high temperatures?

Considering to remove the soft JB Weld paste.

Any other DIY persons able to share experiences?

Attachments

Last edited: