Kelpie

Well-Known Member

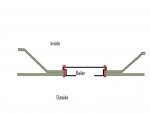

I have a repair to do on a foam-cored dinghy hull. What I'm intending to do is scrape/dremel out the filling between the GRP skins, and then inject epoxy into the void. This is so that I can fit a self-bailer without the bolts crushing the hull skin.

What is the smallest diameter of needle which will be practical in this application? And is there anything I can do to get the epoxy to be as runny as possible to make injecting easier?

What is the smallest diameter of needle which will be practical in this application? And is there anything I can do to get the epoxy to be as runny as possible to make injecting easier?