pearson.henry2

New Member

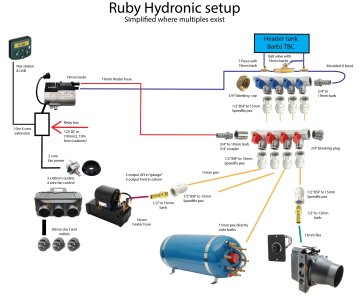

I’m planning a hydronic installation for next winter on our 3 cabin Hanse 370.

Plan is eberspacher d5wsc (5kw hydronic), connected to dual coil calorifier and heating circuit.

Will have valves the classic “summer valve” to isolate calorifier and heating circuit.

Planning on replacing calorifier for a 30 or 40l one under the port aft bunk. Planning on the following matrix heaters:

4.7kw in main saloon.

4.7kw in forepeak

Double duct one to do both aft cabins

Single duct to do heads.

Just a few questions really for anyone with experience of a hydronic system:

What size hydronic unit do you have installed? (And boat size)

How long do you find it takes to heat up your hot water (and what capacity)

How many and of what size (kw) matrix heaters do you have?

Thanks

Plan is eberspacher d5wsc (5kw hydronic), connected to dual coil calorifier and heating circuit.

Will have valves the classic “summer valve” to isolate calorifier and heating circuit.

Planning on replacing calorifier for a 30 or 40l one under the port aft bunk. Planning on the following matrix heaters:

4.7kw in main saloon.

4.7kw in forepeak

Double duct one to do both aft cabins

Single duct to do heads.

Just a few questions really for anyone with experience of a hydronic system:

What size hydronic unit do you have installed? (And boat size)

How long do you find it takes to heat up your hot water (and what capacity)

How many and of what size (kw) matrix heaters do you have?

Thanks