Keith-i

Well-Known Member

I've got a small air leak somewhere in my fuel line which results in a bubble of air collecting at the highest point in the line which happens to be just before the HPFP. There's no diesel leak apparent anywhere and it is not enough air to cause a problem running or starting the engine but its one of those little things I'd love to resolve in case it ever leads to a bigger problem.

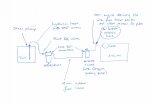

The attached sketch (not my best) shows the layout and the approximate heights of the main items relative to each other. Most of the line is rubber fuel hose, but there is a clear section just before the HPFP at the highest point which is where the air collects. As the fuel level in the tank is below the top of the engine filter and HPFP this part of the sytem would always be running under negative pressure in use. I've tightened all the connections and checked the obvious but to no avail. My suspicion is that it is somewhere downstream of the Separ filter.

Is there any practical way of pressurising the feed in the hope that any leak would show with diesel escaping? I think the practicalities of blocking off the tank vents, fill point and heater pickup would make pressurising the tank itself quite difficult.

The attached sketch (not my best) shows the layout and the approximate heights of the main items relative to each other. Most of the line is rubber fuel hose, but there is a clear section just before the HPFP at the highest point which is where the air collects. As the fuel level in the tank is below the top of the engine filter and HPFP this part of the sytem would always be running under negative pressure in use. I've tightened all the connections and checked the obvious but to no avail. My suspicion is that it is somewhere downstream of the Separ filter.

Is there any practical way of pressurising the feed in the hope that any leak would show with diesel escaping? I think the practicalities of blocking off the tank vents, fill point and heater pickup would make pressurising the tank itself quite difficult.