geem

Well-Known Member

I don't know what you are using but common sense when laying up flat glass sheets to make backing pads is you would use heavy cloth. Probably the heaviest cloth you are likely to use when boat building. From experience, the heaviest cloth most supplier carry. It's quicker to do than say using 7 oz cloth that will take 20 layers or so to get to something substantial enough for the job in hand. Good luckGeem

How do you know what weight glass cloth I am using?. I don't think I need anything like 6mm (¼ in.)

I'll start laying up and continue until I think the strength is adequate.

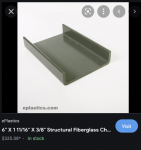

I could of course lay it up in a "U" shape which would give it extra strength.