thinwater

Well-Known Member

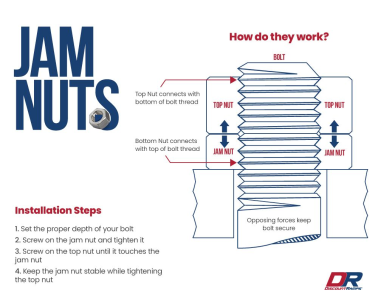

Yes, I should have said tension.Surely you could change the torque just by turning the nut?

Perhaps you mean the bolts will inevitably be subjected to the rigging tension when sailing?

But AFAICT you could still change the tension in the bolt, by pre-tensioning it (assuming the deck can take it), and the rigging tension would then be added to that pre-tension

No, the tension (torque plus rigging) are not additive. Balanced, but not additive.