skippeer

Well-Known Member

2022 did I replace 6 old AGM batteries with 2P4S GBS LFP cells and installed X2 BMS from BatteryBalance.

The old no-name alternator with a Balmar MC-614 regulator from 2011 can charge with 75 A did I monitor last summer when we were day sailing from Netherlands to France.

95% of the nights with shore power so the domestic battery bank was having high SOC all the time, this season I expect that we will be using our anchor a lot and need to improve the alternator capacity.

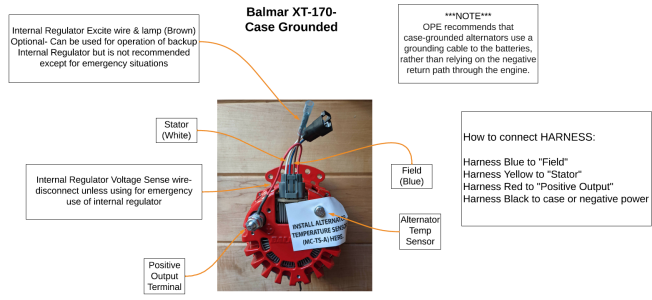

Have payed for a Balmar XT-SF170-J10-KIT (170 A) alternator kit and serpentine pulley rebuild kit, it will take some weeks for the shipment from US and while waiting I am doing some detailed planning.

The old no-name alternator do have a minus & plus terminals and 35 mm2 wires to busbars in the engine compartment.

The new XT alternator is case grounded and I would like to continue use a ground wire connected to the alternator.

Possible connection points:

Anyone with ideas/experience of fixing a perfect electrical minus connection on a case grounded alternator?

The old no-name alternator with a Balmar MC-614 regulator from 2011 can charge with 75 A did I monitor last summer when we were day sailing from Netherlands to France.

95% of the nights with shore power so the domestic battery bank was having high SOC all the time, this season I expect that we will be using our anchor a lot and need to improve the alternator capacity.

Have payed for a Balmar XT-SF170-J10-KIT (170 A) alternator kit and serpentine pulley rebuild kit, it will take some weeks for the shipment from US and while waiting I am doing some detailed planning.

The old no-name alternator do have a minus & plus terminals and 35 mm2 wires to busbars in the engine compartment.

The new XT alternator is case grounded and I would like to continue use a ground wire connected to the alternator.

Possible connection points:

- My VP D2-55 (A) have a 2" single foot and according to Balmar info should a M10 bult be used holding alternator fixed to the engine foot (pivot bolt).

- At the top there are 5 holes for the tension arm, 3 of them have M8 threads, sanding of the paint around one of these holes could be a possible connection point.

- ?

Anyone with ideas/experience of fixing a perfect electrical minus connection on a case grounded alternator?

Last edited: