bluerm166

Well-Known Member

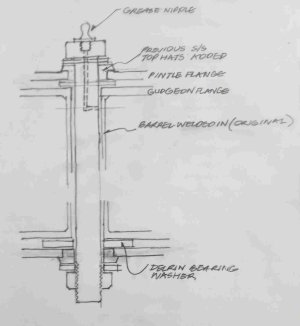

These chunky rudder pintle/gudgeon assemblies fully enclose the 1/2 in bolts where lubrication would be beneficial but I would like to improve things.

From records they seem to have required intervention every ten years or so ,At one time having top hat stainless washers welded into the pintle flanges.This winter the worn bolts ( particularly the top at the neck) were replaced with UNC bolts that have a pretty full shank .

The rudder and stock are hefty and not easily removed when the boat is afloat.So having them disassembled I contemplate drilling vertically down through the hex bolt head

plus sideways to meet this through the shank so that the tube within the gudgeon could be reached by oil if not by grease.The bolts themselves can be tightened solid in the pintle frame so that they do not rotate in it.

Any thoughts on this approach to lubrication please, going so far as to add a greasing nipple on top of the hex ?.

Obviously I can grease before refitting the bolts but this is probably insufficient to last the season/s.

From records they seem to have required intervention every ten years or so ,At one time having top hat stainless washers welded into the pintle flanges.This winter the worn bolts ( particularly the top at the neck) were replaced with UNC bolts that have a pretty full shank .

The rudder and stock are hefty and not easily removed when the boat is afloat.So having them disassembled I contemplate drilling vertically down through the hex bolt head

plus sideways to meet this through the shank so that the tube within the gudgeon could be reached by oil if not by grease.The bolts themselves can be tightened solid in the pintle frame so that they do not rotate in it.

Any thoughts on this approach to lubrication please, going so far as to add a greasing nipple on top of the hex ?.

Obviously I can grease before refitting the bolts but this is probably insufficient to last the season/s.

Last edited: