prv

Well-Known Member

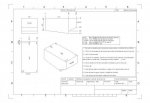

My Nanni engine data sheet states 8mm for the fuel feed but it doesn't say what the fittings are

Almost certainly hose barbs, as the connection to the engine needs to be flexible. Achieving that flexibility with a coil of polished copper pipe looks very nice in a narrowboat or steam launch, but is unlikely to be what Nanni have in mind

What you should have on the tank depends on what you're planning to fit between tank and engine. Personally I prefer hose everywhere, as I reckon quality reinforced hose is actually probably stronger than thin-walled copper tubing. But some people worry about the hose burning through in a fire, or believe that metal is automatically more robust, and run copper from the tank to a point just next to the engine, bridging the gap with a short length of hose. You won't be running a single continuous length from tank to engine anyway, as the primary filter needs to go in between, and preferably a stop tap too. If the tank is in the engine space, there is perhaps an argument for copper from the tank to a nearby valve, to be closed in case of fire, and hose after that. I've inherited valves mounted directly on the tank banjos, with hoses thereafter, and I plan to eventually make the valves cable-operated from an "emergency fuel cut-off" pull-handle outside the engine box.

Pete

Last edited: