Ian_Edwards

Well-Known Member

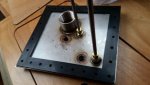

I want to fit a stand pipe to a Vetus Atank390, 1400 long x 800 deep x 400wide. Wall thickness 5-7mm.

The tank looks like it is a rotation moulded, and the spec' says synthetic, whatever that means, it looks like some form of polythene to me.

I have no internal access to the tank, at least at the end I want to fit the standpipe.

The standpipe is for a diesel heater, so it doesn't need to go to the bottom of the tank , 700mm would work well, 650mm would do, and the output need to fit a standard 5mm ID rubber hose.

I'm having difficulty finding a standpipe that will fit the bill.

Length seems to be a problem, as does the wall thickness (most seem to be for thin steel tanks), and of course the lack of internal access.

It really needs to be SS steel of some form.

Has anyone successfully fitted a standpipe, to a Vetus tank, where internal access isn't practical?

The tank looks like it is a rotation moulded, and the spec' says synthetic, whatever that means, it looks like some form of polythene to me.

I have no internal access to the tank, at least at the end I want to fit the standpipe.

The standpipe is for a diesel heater, so it doesn't need to go to the bottom of the tank , 700mm would work well, 650mm would do, and the output need to fit a standard 5mm ID rubber hose.

I'm having difficulty finding a standpipe that will fit the bill.

Length seems to be a problem, as does the wall thickness (most seem to be for thin steel tanks), and of course the lack of internal access.

It really needs to be SS steel of some form.

Has anyone successfully fitted a standpipe, to a Vetus tank, where internal access isn't practical?