Baggywrinkle

Well-Known Member

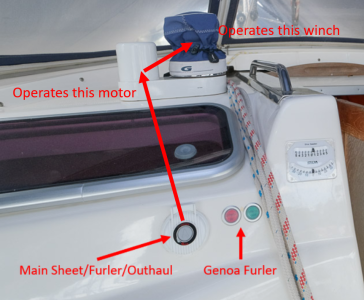

The red/green buttons are labelled and illuminated and look like this ...I don't see any labels on the buttons?

The other button is fairly obvious once the crew know what the red/green buttons do.

The ones for the genoa sheet winches are only safe to operate from the helm, and I ensure the crew are told what the buttons do before they are allowed near them. They are also shut off at the battery when we are not using the sails.

Crew are also told that if they don't know what a button does, then don't press it, just ask and I will explain ... some of the symbols on the Bavaria switch panels are not exactly self-explanatory, but if I ever add electric drives to the code-zero/spinnaker winches, I'll label them all as the buttons will be next to the genoa sheet winch buttons.